Introduction:

The manufacturing industry is evolving rapidly, and one of the most significant advancements in recent years is the automation of packaging processes. Packaging robots have transformed the way manufacturers operate, driving efficiency, reducing labor costs, improving product quality, and accelerating production timelines. With the increasing demand for personalized products and more flexible packaging solutions, robotics and automation have become essential to meeting these challenges.

Packaging robots are not only enhancing manufacturing efficiency but also playing a pivotal role in addressing the growing trend of product customization. This shift towards mass customization has created new opportunities and challenges for manufacturers, requiring them to be agile, cost-efficient, and capable of delivering tailored packaging solutions. In this article, we explore how packaging robots are shaping the future of manufacturing efficiency, particularly in terms of customization and personalization.

Get FREE Sample: https://www.nextmsc.com/packaging-robots-market/request-sample

1. The Role of Packaging Robots in Manufacturing Efficiency

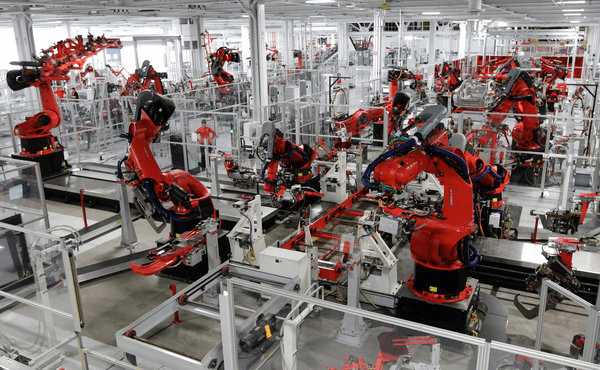

Automation in packaging has been a game-changer for manufacturers across various industries, from food and beverage to electronics, pharmaceuticals, and consumer goods. Traditional packaging processes were labor-intensive, slow, and prone to human error. Packaging robots have revolutionized this process by performing tasks like sorting, labeling, sealing, and filling with precision, speed, and consistency.

These robots are designed to work tirelessly, maintaining high performance even in high-volume production environments. By automating repetitive tasks, manufacturers have been able to increase throughput, reduce costs, and enhance operational efficiency. Robots not only optimize the physical packaging process but also help in ensuring that quality standards are consistently met, preventing defects, waste, and delays.

2. The Growing Demand for Customization in Packaging

Consumers today expect products to be more personalized than ever before. Whether it’s customized designs, limited-edition packaging, or products tailored to individual preferences, the demand for personalization is on the rise. This shift toward personalized products requires manufacturers to adopt more flexible, adaptable packaging solutions that can accommodate a wide range of product sizes, packaging designs, and customer requirements.

Packaging robots are key enablers of this shift towards customization. Unlike traditional packaging lines that were typically designed for mass production with limited flexibility, modern packaging robots are highly versatile and can be easily reprogrammed to handle different product types, sizes, and packaging configurations. This ability to adapt quickly allows manufacturers to offer customized packaging options to meet specific consumer demands without sacrificing speed, efficiency, or cost-effectiveness.

3. How Packaging Robots Meet the Growing Demand for Personalized Products

As the demand for personalized products continues to grow, manufacturers must find ways to streamline the packaging process while maintaining the ability to create unique, customized packages for each product. Packaging robots have emerged as a solution to this challenge, offering several advantages that make it easier for manufacturers to meet the needs of today’s consumers:

Increased Flexibility

One of the key benefits of packaging robots is their ability to offer flexible solutions for different types of products and packaging configurations. Robots can be programmed to handle various sizes, shapes, and designs, enabling manufacturers to easily switch between different product lines. For example, a robot designed for packaging bottles of different shapes and sizes can be reprogrammed to accommodate a new product line without requiring significant downtime or reconfiguration of the entire production system.

This level of flexibility is crucial in a world where consumers expect more variety and customization. Whether it’s a seasonal product with special packaging, a limited-edition item with a unique design, or a product that requires individualized labeling or instructions, packaging robots can handle these changes with ease.

Speed and Efficiency in Customization

Customization is often associated with increased lead times and costs, especially when it comes to packaging. However, packaging robots are capable of achieving high speeds while maintaining precision, allowing manufacturers to provide customized products without significantly increasing production time or costs. Robots can automate tasks like printing personalized labels, applying unique packaging designs, or sorting products based on specific consumer preferences.

For example, in the food and beverage industry, robots can be programmed to package products with varying labels based on dietary preferences (such as gluten-free, vegan, or organic). Similarly, in the cosmetics industry, robots can quickly package limited-edition items with specialized labels and designs, all while maintaining high efficiency.

Consistency in Quality

Customization does not mean sacrificing quality. Packaging robots are equipped with advanced sensors and machine vision systems that ensure every package meets the highest standards. Whether it’s ensuring the correct label is applied or verifying the accuracy of custom packaging designs, robots can detect and correct errors in real-time, preventing defects from reaching consumers.

This level of precision is particularly important when handling custom packaging, as inconsistencies can lead to customer dissatisfaction and damage to the brand’s reputation. Robots’ ability to perform quality checks at every stage of the packaging process ensures that even highly customized packages are produced to the highest standards, without error.

Reduced Labor Costs and Human Error

The labor costs associated with manual packaging are significant, especially when dealing with customized products that require more attention to detail. By automating the packaging process, manufacturers can reduce the need for labor-intensive tasks and minimize the risk of human error.

Packaging robots can also work 24/7 without fatigue, increasing productivity and ensuring that the packaging process remains efficient even during peak production periods. This is particularly beneficial in industries where high-volume production meets the demand for customization, such as the apparel, electronics, and cosmetics industries.

4. Packaging Robots and Customization in Specific Industries

Food and Beverage Industry

In the food and beverage industry, customization plays a significant role in attracting consumers, especially with seasonal promotions, limited-edition products, and personalized packaging. Packaging robots help manufacturers meet these demands by automating the creation of custom labels, packaging designs, and sorting processes. With packaging robots, food producers can offer customized packaging for different regions, dietary preferences, and promotional periods without interrupting production schedules.

Cosmetics and Personal Care

The cosmetics industry thrives on customization, with consumers increasingly looking for personalized products that suit their individual preferences. Packaging robots play a crucial role in this trend by providing the flexibility to handle different product sizes, shapes, and packaging formats. Whether it’s personalized skincare products, custom-designed packaging, or limited-edition releases, robots help cosmetic manufacturers create unique and attractive packaging quickly and efficiently.

Electronics and Consumer Goods

As the demand for personalized gadgets and tech products grows, packaging robots help electronic manufacturers customize packaging for a wide range of products. From special edition smartphones to custom packaging for accessories, robots ensure that these products are efficiently packaged according to specific consumer requirements. By automating the packaging process, manufacturers can keep up with the increasing need for customized product offerings without compromising on speed or accuracy.

5. The Future of Packaging Robots and Customization

As technology continues to advance, the role of packaging robots in customization is only set to grow. The integration of artificial intelligence (AI), machine learning, and robotics will further enhance the capabilities of these systems, allowing them to handle even more complex customization tasks. AI-powered robots will be able to analyze consumer preferences and trends, adapting packaging designs and processes accordingly to meet ever-changing demands.

Furthermore, the rise of sustainable packaging and eco-friendly materials is likely to become a key factor in customization. Packaging robots will need to incorporate new materials and eco-friendly practices, offering manufacturers the ability to create customized packages that align with environmental goals.

The future of packaging robots lies in greater autonomy, adaptability, and intelligence. As the demand for personalized products continues to rise, packaging robots will play a central role in ensuring manufacturers can meet consumer expectations for tailored, high-quality products at competitive speeds.

6. Conclusion

Packaging robots have revolutionized the manufacturing industry by offering solutions that enhance efficiency, precision, and customization. As consumer demand for personalized products continues to rise, these robots will play an increasingly important role in meeting the challenge of mass customization. By providing manufacturers with the flexibility, speed, and precision required to meet today’s market demands, packaging robots are shaping the future of manufacturing efficiency.

With the continued development of AI, machine learning, and advanced robotics, the potential for further innovation in the packaging sector is vast. As industries across the globe embrace automation, packaging robots will remain at the forefront of transforming how products are packaged, customized, and delivered to consumers.

Read the complete blog: https://www.nextmsc.com/blogs/shaping-the-future-the-transformative-impact-of-packaging-robots-on-manufacturing-efficiency

Write a comment ...